Precision Mold Components Supplier With 23+ Years Of OEM / ODM Experience

Custom & Standard Ejector Pins/Sleeve Manufacturer In China

- 10,000+ Standard Sizes In Stock For Immediate Shipment

- 1pc MOQ for Custom Ejector Pins

- 2–5 Days Sample Lead Time | 3–7 Days Mass Production

- SKD61 / SKH51 / H13 / 1.2344 Material Options | HRC 58–64

- ±0.002mm Tolerance | 100% Inspection | 24H Quotation

±0.002mm Accuracy | Mirror Polish Finish

Full Inspection Before Shipment | HRC 58–64 Hardness

Support Drawing, Sample, or Standard Size Customization

8000㎡ Factory • 80+ Technicians • Fast Sampling & Mass Production

Exported to 50+ Countries | Long-Term Partners Worldwide

Trusted by Automotive, Electronics, and Medical Mold Makers

Ejector Pin Display – Standard & Custom Options Available

Thousands of standard ejector pins ready to ship in 2-3 days — custom designs available for any mold specification.

Widely-used standard ejector pins made from 65Mn and SKD61 materials, covering diameters Ø0.8–25 mm and lengths up to 600 mm — in stock and ready to ship within 3 days.

-

Material: 65Mn / SKD61

Length Range: 100–600 mm - Hardness: HRC 52 ± 2 (65Mn) | HRC 58–62 (SKD61)

- Features: High precision, smooth ejection, long-lasting durability

- Surface Finish: Polished, Nitrided, or TiN Coated

- Availability: Over 10,000 standard models in stock | Ready to ship in 2-3 days

Custom-manufactured round ejector pins for special mold structures and precision applications, available in various materials, coatings, and dimensions.

- Material: H13 / SKH51 / 1.2344 / ASP23 or others available for custom orders

- Hardness: HRC 58–66 depending on material and surface treatment

- Tolerance: ±0.002 mm for critical dimensional accuracy

- Surface Finish: TiN / TiAlN / DLC coating optional for enhanced wear and heat resistance

- Application: Designed for non-standard molds, high-temperature, or long-cycle precision tooling

Precision flat ejector pins specially designed for thin-wall or narrow-section mold parts, ensuring smooth ejection and minimal deformation during demolding.

- Material: SKH51 / ASP23 optional for special wear-resistant molds

- Hardness: HRC 58–62 after vacuum heat treatment and nitriding

- Tolerance: Width & thickness ±0.005 mm | Length ±0.02 mm

- Surface Finish: Mirror-polished / Nitrided / TiN or DLC coating optional for anti-galling and wear protection

- Application: Ideal for thin and flat parts ejection in plastic molds, die-casting molds, and precision tooling

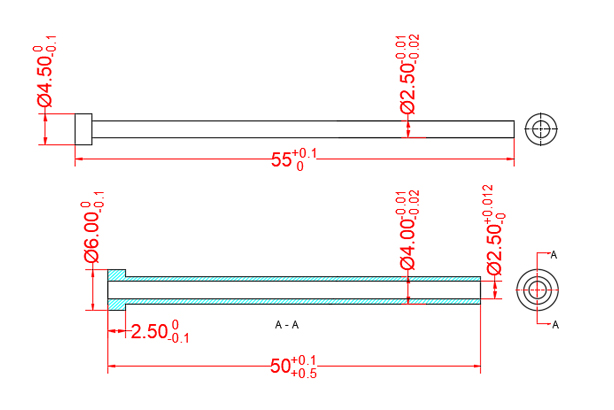

Precision stepped ejector pins designed for deep-cavity and thin-wall molds, providing stable ejection force and preventing part deformation.

- Material: SKH51 / ASP23 optional for wear-resistant or high-temperature molds

- Hardness: HRC 58–62 after vacuum heat treatment and nitriding

- Tolerance: ±0.002 mm | Concentricity ≤ 0.005 mm

- Surface Finish: Polished / Nitrided / TiN or TiAlN coating optional for enhanced lifespan

- Application: Ideal for deep-cavity molds, precision ejection, and complex part demolding

Tailor-made insert ejector pins manufactured according to customer drawings or samples, ensuring precision fitting for complex and non-standard mold structures.

- Material: SKD61 / H13 / 1.2344 / ASP23 / Tungsten Carbide for customized orders

- Hardness: HRC 58–64 after vacuum heat treatment and surface nitriding

- Tolerance: ±0.002 mm for precision fit and interchangeability

- Surface Finish: Polished, Nitrided, or TiN / DLC coated for superior wear resistance

- Application: Suitable for special-shaped molds, multi-cavity molds, and deep-cavity ejection systems

High-wear, high-temperature ejector pins made from SKH51, SKD61 and stainless steel, engineered for durability, precision and demanding mold applications.

- Material Options: SKH51 / SKD61 / Stainless Steel (316/420) available depending on application environment.

- Hardness: HRC 58-66 after vacuum heat treatment or nitriding (material and treatment dependent).

- Tolerance & Precision: ±0.002 mm (for critical fit dimensions)

- Surface Finish / Coating: Mirror polish, nitrided, or optional coatings such as TiN / TiAlN / DLC for enhanced wear and heat resistance.

- Application Scope: Ideal for high-temperature molds, stainless material molds, high-cycle production and precision tooling assemblies.

Precision straight sleeves designed for mold guiding and ejection systems, ensuring stable alignment, smooth motion, and long service life under high-load or high-temperature conditions.

- Material: SUJ2 / SKD61 / 40Cr / Stainless Steel (optional for corrosion-resistant molds)

- Hardness: HRC 58–64 (SKD61) | HRC 52–56 (SUJ2 or 40Cr) after heat treatment

- Tolerance: ±0.002 mm for inner / outer diameter accuracy

- Surface Finish: Precision ground, nitrided or QPQ / DLC / TiN coated for improved wear resistance

- Application: Ideal for plastic injection & die-casting molds, ensuring high-precision guiding and ejection stability

Precision shoulder sleeves designed for precise mold alignment, stable guiding, and secure seating between mold plates. The shoulder structure ensures accurate positioning, improved strength, and easy assembly for both injection and die-casting molds.

- Material: SUJ2 / SKD61 / 40Cr / Stainless Steel (optional for anti-corrosion use)

- Hardness: HRC 58–64 (SKD61) | HRC 52–56 (SUJ2 or 40Cr) after heat treatment

- Tolerance: ±0.002 mm for critical inner/outer diameters and shoulder dimensions

- Surface Finish: Precision ground, nitrided, or QPQ / TiN / DLC coating optional for superior wear and rust resistance

- Application: Ideal for injection molds, stamping dies, and die-casting molds where accurate positioning and long-term durability are required

High-precision core pins engineered for forming holes, cavities, and complex internal features in injection molds and die-casting tools. Custom sizes, materials, and coatings available for high-temperature and high-wear applications.

- Precision core pins engineered for forming holes, cavities, and complex internal features in injection molds, stamping dies, and die-casting tools.

- Manufactured with tight tolerances to ensure stable dimensional accuracy, smooth molding performance, and consistent part quality in high-cycle production.

- High-strength core pin construction designed to withstand high temperatures, heavy loads, and repeated thermal stress in demanding molding environments.

- Precision-ground and EDM-finished surfaces provide excellent wear resistance, reduced friction, and long service life during continuous mold operation.

- Ideal for OEM mold makers requiring reliable, custom core pins that improve tooling performance, enhance product accuracy, and reduce maintenance downtime.

Need Precise Punch Pins for Stamping?

Need Detailed Specs for Guide Posts & Bushings?

Factory Strength & Advanced Machining

Our ejector pins are produced in a modern 8,000 m² facility equipped with 5-axis CNC centers, centerless grinding, and automatic polishing machines.

Every process is precisely controlled to achieve ±0.002 mm tolerance, ensuring perfect fit and smooth ejection in every mold.

Why Choose HTX Factory

Over 23 years of OEM & ODM experience — trusted by 8,000+ partners worldwide.

1️⃣ Expert Engineering Support

1. 15+ Years Experience, 24/7 Support

2. Optimize Drawing & Material for Durability

3. Early Design for Precision & Strength

4. Fast Quote 10mins, Samples 2–5 Days

5. 1-on-1 Customization, 4H Urgent Sample

6. Free Custom LOGO & Label Service

7. Complete Tech Files & Digital Catalog

2️⃣ Strict Quality & Precision Control

1. 86 Experts + 20 QC Team

2. ±0.002mm Precision, 100% Inspection

3. Imported Steel, +20% Lifespan

4. Free Replacement for Quality Issues

5. Bulk ≠ Sample? Free Replacement

6. Not As Ordered? Free & Fast Replace

7. Pin Break? 1H Quick Solution

3️⃣ Fast & Flexible Service Guarantee

1. MOQ 1pc, Rush Order Priority

2. Bulk Delivery in 3–7 Days

3. Real-Time Production Tracking

4. 1h Fast Response, 24h Solution

5. Free LOGO & Package Customization

6. Lead Time Shortened by 30%

7. 7-Day After-Sales Follow-Up

4️⃣ Reliable Partnership Assurance

1. Full Compensation for Non-Human Issues

2. 7-Day After-Sales Follow-Up

3. Factory Direct, 10–20% Lower Price

4. Delay Compensation Guarantee

5. Confidentiality Agreement

6. Free Factory Visit & One-on-One Service

Ejector Pin Customization

Support customized ejector pin production based on customer 2D/3D drawings, samples, or precision requirements.

Fully Customizable

Custom Ejector Pins for Injection, Die-Casting & Precision Molds

- Material Options: SKD61 / SKH51 / H13 / 1.2344 / 1.2343 / ASP23 / Stainless Steel (Custom alloys optional)

- Head Type: Flat head / Dome head / Step type / Shouldered / Custom shapes

- Tolerance: ±0.002 mm (Precision grinding & concentricity ≤ 0.005 mm)

- Surface Treatment: Nitriding / TiN / TiAlN / QPQ / DLC / Mirror polishing / Heat treatment (vacuum type available)

- Hardness: HRC 55 – 66 (depending on material & process)

- Application: Ideal for injection molds, die-casting molds, and high-precision ejector systems

- OEM Service: Custom dimensions, drawings, coatings, packaging, and logo engraving accepted

Advanced Surface Treatments

Enhance hardness, corrosion resistance, and overall performance of ejector pins with advanced finishing options.

Each surface treatment is engineered to improve wear resistance, smoothness, and service life under different mold environments — from high-temperature injection molds to precision medical tooling.

Heat Treatment

Optimizes the internal structure for high strength and stability. → Harder, tougher, and more durable under continuous cycles.

Nitriding

Creates a hard, wear-resistant surface layer through controlled nitrogen diffusion. → Improves fatigue resistance and lifespan in high-temperature molds.

Polishing

Mirror-finish surface to minimize friction and sticking. → Ensures smooth ejection and enhances appearance.

PVD Coating (TiN / TiAlN / DLC)

Physical vapor deposition coating adds extreme hardness and heat resistance. → Excellent anti-adhesion and wear protection for precision molds.

Hard Chrome Plating

Adds a dense chromium layer for corrosion and oxidation resistance. → Ideal for humid or long-term storage environments.

Stainless Steel Passivation

Removes free iron and enhances the natural oxide film of stainless steel. → Improves anti-rust performance and chemical stability.

Nickel Plating

Provides uniform coating thickness and chemical corrosion protection. → Recommended for ejector pins used in chemical or food-grade molds.

Black Oxidation (Blackening)

Protective oxidation film adds light lubrication and aesthetic finish. → Economical, rust-preventive, and reduces glare.

Our Factory

- Professional supplier for overseas stamping,injection molding,and die-casting parts manufacturers,mold makers,large equipment integrators,and service providers.

- 23+ years of experience in customized non-standard mold components OEM & ODM manufacturing.

- Over 8,000㎡ factory with 100+ imported Japanese machines.

- Daily capacity of 12,000+ pcs, bulk production delivered within 3–7 days (stable lead time).

- 18+ professional testing devices (2.5D, CMM, Mitutoyo projector, optical microscope).

- 86+ technicians with over 10 years of industry experience.

- Sufficient stock of various material grades with stable pricing.

- ERP intelligent production scheduling management system.

- 9,000+ product categories serving 8,000+ companies.

Quality Inspection Process

Ensuring Precision from Start to Finish-Each ejector pin goes through strict 3-step inspection — from raw material to final shipment — guaranteeing consistent quality and precision that meet international mold standards.

Incoming Material Inspection

Verify hardness, diameter, and surface finish before machining.

In-Process Inspection

Real-time measurement during machining ensures ±0.002 mm accuracy.

Final Quality Check

100% inspection before shipment — every ejector pin verified for precision.

Our Partners

Trusted by 50+ Global Partners • DuPont • BYD • Foxconn • Midea • Gree …

Our Customer

Certification and Patents

Common Questions

Most Popular Questions.

We have listed some questions you may ask. If you have more inquiries about our products, you can send an inquiry to contact us.

Standard pins are 65Mn or SKD61; custom pins can be stainless steel (304/420/440C), SKD11, DC53, ASP23, or customer-specified materials.

Yes, we can customize pins from 5mm to 200mm in length and various diameters, ensuring perfect mold fit.

The minimum order quantity is 1 piece, suitable for fast prototyping and mold debugging.

Depending on size, quantity, and surface treatment, custom pins are shipped in 5–7 days, standard pins in 2–3 days.

With precision machining and high-quality materials, combined with proper surface treatment, pins are durable for long-term use and provide stable ejection, minimizing part damage.

Yes, we can provide samples for mold trial and verification, ensuring pins perfectly match the mold before mass production.

Talk Directly to the Factory — Get Samples Fast!

Skip the middleman, save your cost, and start your project faster with samples directly from our factory.

Request Your Sample — See Our Quality in Action!

Precision manufacturing, reliable quality, and fast delivery — just fill out the form to get started.