Precision Mold Guide System Supplier with 23+ Years of OEM / ODM Experience

Custom & Standard Guide Posts and Bushings Manufacturer in China

- 10,000+ Standard Sizes Ready for Immediate Shipment

- 1pc MOQ for Standard Guide Posts & Bushing

- 2–5 Days Sampling | 3–7 Days Fast Mass Production

- SUJ2 / 20Cr / 8620 / H13 / Brass / Graphite-Copper Options

- ±0.002mm Tolerance | 100% Inspection | 24H Quotation

±0.02mm Accuracy | Mirror-Polished Finish | HRC 58-64 Hardness

Each guide post and bushing is CNC-machined and centerless-ground for ultra-smooth guiding.

1-Piece MOQ | Customized Size & Structure | 2-5 Days Sampling

Support 2D / 3D drawing-based customization — including flanged types, ball guide sets, oil-groove designs, and special surface treatments (TD / DLC / QPQ).

Exported to 50 + Countries | ISO 9001 & IATF 16949 Certified

23 + years of experience serving automotive, electronic, die-casting and automation industries.

Guide Posts & Bushings Display – Standard & Custom Options Available

Thousands of standard guide posts & bushings ready to ship within 3 days — custom designs available for any mold application.

High-precision guide post and bushing sets for most molds, compatible with standard mold bases.

- Made of SUJ2 / 20Cr steel, HRC 58–62 hardness

- Precision tolerance ±0.002 mm ensures perfect fit

- Over 10,000 standard sizes available, ready to ship in 2–3 days

- Fully interchangeable with DME / HASCO / MISUMI

- Ideal for injection molds, stamping dies, and automation tooling

Designed for high-precision molds, featuring ball-cage guiding for ultra-smooth motion and longer life.

- Ball-cage structure reduces friction and improves accuracy

- Smooth guiding extends mold lifespan

- Ideal for high-speed, precision stamping and plastic molds

- Optional materials: SUJ2 / H13 / SKD61 with HRC 58-62

- Supports custom dimensions and OEM requests

Flange design provides rigid positioning and easy replacement for heavy-load mold applications.

- Flange seat enhances mounting strength and alignment

- Easy drop-in replacement for standard mounts

- Materials: 8620 / 20Cr / Brass / Graphite-Copper optional

- Surface coating: Chrome / Black Oxide / DLC

- Perfect for die-casting & press molds

Embedded graphite plugs ensure constant lubrication — ideal for precision molds and high-cycle tooling.

- Graphite-copper alloy body with embedded lubricant plugs

- Self-lubricating — no need for external grease or oil

- Perfect for precision, high-speed molds and die-casting systems

- Reduces maintenance frequency and tooling downtime

- Service life extended by 30–50% compared to standard bushings

Smooth sliding motion with high concentricity, designed for stable guiding under high loads.

- Precision ground SUJ2 / 8620 / 20Cr materials

- Ultra-smooth sliding fit with low friction

- ±0.002 mm tolerance for precise alignment

- Ideal for molds, automation equipment, and general machinery

- Cost-effective solution with long service life

High-performance bushings made of brass or bronze for excellent wear resistance and thermal stability.

- Copper-based alloy for high wear and corrosion resistance

- Excellent heat dissipation for high-temperature molds

- Optional graphite plugs for self-lubrication

- Suitable for plastic, die-casting and automation molds

- 30–50 % longer lifespan than standard bushings

Durable guide pins engineered for smooth guide post and bushing motion, offering consistent alignment and extended tool life in high-load mold systems.

- Integrated base for easy mounting and replacement

- Double-spring or ball-guiding structure for stable return

- Suitable for die-casting, injection, and stamping molds

- Supports large-diameter and long-stroke configurations

- Fully compatible with TUB / TUR standard systems

Enhanced surface treatments for extreme mold conditions — longer life and stable operation.

- Coating options: Nitriding / TD / DLC / QPQ / Black Oxide

- Increases hardness and wear resistance by 30–80 %

- Prevents corrosion and galling under load

- Ideal for automotive & die-casting molds

- Fits standard and custom guide sizes

Need Precise Punch Pins for Stamping?

Looking for High-Performance Ejector Pins?

Factory Strength & Advanced Machining

Our factory is equipped with 5-axis CNC centers, precision grinding, EDM, wire-cutting, and automatic polishing machines across an 8,000 m² modern facility.Our guide posts and bushings are produced in a dedicated machining workshop equipped with advanced CNC turning centers, cylindrical grinders, internal & external grinders, coordinate boring machines, and precision honing equipment.

We also apply high-precision reaming and finish grinding to ensure perfect concentricity and smooth motion between the post and bushing.

Every process is strictly controlled under ISO 9001 & IATF 16949 standards, ensuring every part meets ±0.002 mm tolerance for perfect fit and smooth operation in every mold.

Why Choose HTX Factory

Over 23 years of OEM & ODM experience — trusted by 8,000+ partners worldwide.

1️⃣ Expert Engineering Support

1. 15+ Years Experience, 24/7 Support

2. Optimize Drawing & Material for Durability

3. Early Design for Precision & Strength

4. Fast Quote 10mins, Samples 2–5 Days

5. 1-on-1 Customization, 4H Urgent Sample

6. Free Custom LOGO & Label Service

7. Complete Tech Files & Digital Catalog

2️⃣ Strict Quality & Precision Control

1. 86 Experts + 20 QC Team

2. ±0.002mm Precision, 100% Inspection

3. Imported Steel, +20% Lifespan

4. Free Replacement for Quality Issues

5. Bulk ≠ Sample? Free Replacement

6. Not As Ordered? Free & Fast Replace

7. Pin Break? 1H Quick Solution

3️⃣ Fast & Flexible Service Guarantee

1. MOQ 1pc, Rush Order Priority

2. Bulk Delivery in 3–7 Days

3. Real-Time Production Tracking

4. 1h Fast Response, 24h Solution

5. Free LOGO & Package Customization

6. Lead Time Shortened by 30%

7. 7-Day After-Sales Follow-Up

4️⃣ Reliable Partnership Assurance

1. Full Compensation for Non-Human Issues

2. 7-Day After-Sales Follow-Up

3. Factory Direct, 10–20% Lower Price

4. Delay Compensation Guarantee

5. Confidentiality Agreement

6. Free Factory Visit & One-on-One Service

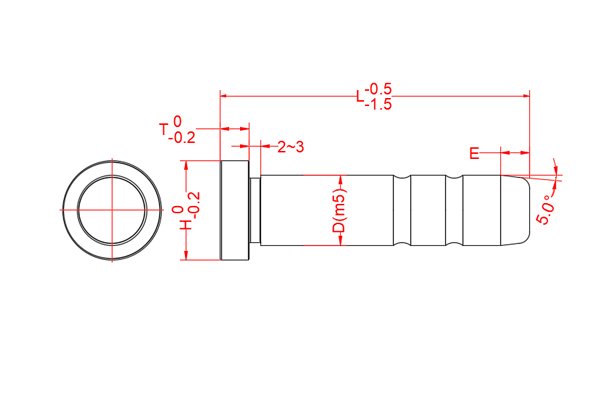

Guide Post & Bushing Customization

Support customized production based on customer 2D/3D drawings, samples, or special precision requirements.

Fully Customizable

Custom Guide Posts & Bushings For Injection, Die-Casting & Precision Molds

-

🔹 Material Options: SUJ2 / 20Cr / 8620 / SKD61 / H13 / Brass / Bronze / Graphite Copper

Optional alloy steels for high-load & anti-wear molds -

🔹 Type & Structure: Plain / Flanged / Shoulder / Self-Lubricating / Graphite Plugged / Split Type

Support for both standard interchange & custom-fit guiding sets -

🔹 Tolerance & Precision: ±0.002 mm tolerance via precision grinding, reaming, and honing

Perfect concentricity and smooth motion under high-speed mold cycles -

🔹 Surface Treatment: Nitriding / QPQ / Nickel / TiN / DLC / Mirror polishing

Enhanced hardness, wear resistance, and corrosion protection - 🔹 Hardness: HRC 58–62 (depending on material and process)

-

🔹 Application: Injection molds, die-casting tools, stamping dies, and automation systems

Stable guiding, high load-bearing, long life - 🔹 OEM Service: Custom dimensions, coatings, packaging, and logo engraving accepted

Advanced Surface Treatments for Longer Mold Life

Enhance hardness, wear resistance, and corrosion protection of guide posts and bushings with our comprehensive finishing options.

Each surface treatment is precisely engineered to deliver smooth motion, reduced friction, and stable performance — even under high-load or high-temperature mold environments.

Carburizing

Enhance surface hardness and impact resistance

Vacuum treatment

Improve surface hardness and wear resistance

Nitriding

Increase surface hardness and wear resistance, reduce friction

Chrome plating

Improve wear resistance and surface finish, corrosion-resistant

Phosphating

Rust protection, enhance adhesion for subsequent treatments

Quenching & tempering

Enhance overall strength and toughness

Blackening

Rust-proof, anti-reflective, aesthetic finish

TD coating

Maximize wear resistance, extend service life

Our Factory

- Professional supplier for overseas stamping,injection molding,and die-casting parts manufacturers,mold makers,large equipment integrators,and service providers.

- 23+ years of experience in customized non-standard mold components OEM & ODM manufacturing.

- Over 8,000㎡ factory with 100+ imported Japanese machines.

- Daily capacity of 12,000+ pcs, bulk production delivered within 3–7 days (stable lead time).

- 18+ professional testing devices (2.5D, CMM, Mitutoyo projector, optical microscope).

- 86+ technicians with over 10 years of industry experience.

- Sufficient stock of various material grades with stable pricing.

- ERP intelligent production scheduling management system.

- 9,000+ product categories serving 8,000+ companies.

Guide Post & Bushing Quality Inspection

Ensuring Precise Alignment From Steel Bar to Assembled Set – Each guide post and bushing set goes through strict 3-step inspection, from raw material and heat treatment to paired sliding-fit tests — guaranteeing stable guidance and long service life for your molds.

Incoming Material & Heat Treatment Inspection

Verify steel grade, hardness and straightness before machining.

In-Process Dimensional & Concentricity Inspection

Real-time measurement during machining — concentricity and diameter within ±0.002 mm.

Final Pairing, Sliding-Fit Test & 100% Check

100% paired inspection before packing — every guide post & bushing set tested for smooth motion.

Our Partners

Trusted by 50+ Global Partners • DuPont • BYD • Foxconn • Midea • Gree …

Our Customer

Certification and Patents

Common Questions

Most Popular Questions.

We have listed some questions you may ask. If you have more inquiries about our products, you can send an inquiry to contact us.

Guide posts are commonly available in SUJ2 / 20Cr / SKD61 / H13 / 8620.

Bushings are produced in brass, bronze, graphite-copper alloy, steel + oil grooves, or self-lubricating embedded graphite.

Custom materials can also be supplied upon request.

Yes. We support:

Non-standard lengths and diameters

Special shoulders, flanges, and split-type bushings

Ball cage type / oil groove type / self-lubricating graphite plug type

High-temperature or wear-resistant coatings (TD / DLC / QPQ / Nitriding)

We can manufacture fully according to your 2D/3D drawings, samples, or design requirements.

For standard sizes: no MOQ (1 pc is acceptable).

For custom sizes: MOQ depends on structure, usually 5–10 pcs.

Standard sizes: Ready to ship in 2–3 days

Custom guide posts: 3–7 days

Custom guide bushings: 5–10 days (depending on structure & coating)

Urgent orders can be expedited.

Yes — each guide post & bushing set is paired and sliding-tested before shipment:

Diameter tolerance: ±0.002 mm

Concentricity: ≤0.003 mm

Smooth sliding fit without play or sticking

Every set undergoes 100% inspection.

Our long-life design supports:

HRC 58–64 hardness for guide posts

High wear-resistant bronze / graphite copper / steel bushings

Optional TD / DLC / QPQ coatings improving life by 30–80%

Self-lubricating graphite plugs for maintenance-free operation

Service life varies according to mold speed, load, and lubrication.

Talk Directly to the Factory — Get Samples Fast!

Skip the middleman, save your cost, and start your project faster with samples directly from our factory.

Request Your Sample — See Our Quality in Action!

Precision manufacturing, reliable quality, and fast delivery — just fill out the form to get started.